Membrane technologies

Membrane separation can be divided into two categories according to the type of separated substance:

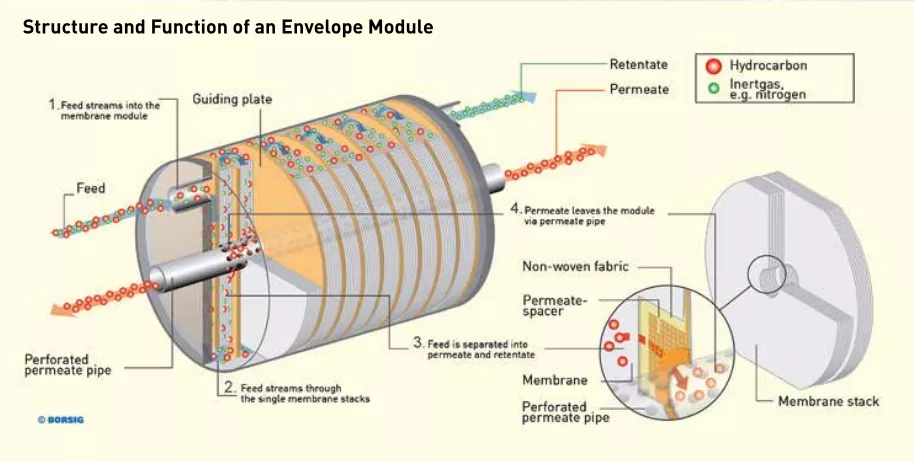

- Membrane separation of gases/vapors

- Separation and recovery of hydrocarbons

- Solvent-resistant flat membranes for use in gas/vapor separation

- Hydrogen recovery and purification (H2)

- Hollow fiber membranes for gas purification and H2 recovery and enrichment

- CO2 separation and enrichment

- Flat sheet membranes for gas purification and carbon capture

- Separation and recovery of hydrocarbons

- Membrane separation of organic liquid mixtures

- Nanofiltration of organic solvents (OSN_ Organic Solvent Nanofiltration)

- Solvent-resistant flat membranes for use in gas/vapor separation and nanofiltration of organic solvents (OSN).

- Pervaporation

- Solvent-resistant flat membranes for pervaporation, i.e. selective separation of water or methanol

- Nanofiltration of organic solvents (OSN_ Organic Solvent Nanofiltration)

If a higher level of separation is required, secondary separation technologies can be used:

- Pressure swing adsorption (PSA)

- Temperature swing adsorption

- Absorption

- Distillation

- Condensation (liquefaction)

- Thermal or catalytic oxidation

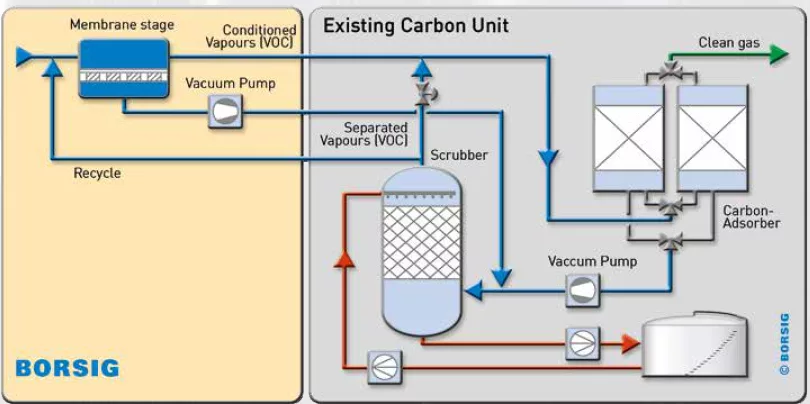

Retrofit of Existing Active Carbon Recovery Systems

- in case more capacity is required e.g. due to increased transshipment

- Performance loss of the carbon beds due to accumulation of heavy or aromatic hydrocarbons or contamination by impurities e.g. sulphuric components

- The performance of the existing unit is not efficient enough to meet the required emission level

- New product vapours have a negative impact on the active carbon or cannot be adsorbed and must be separated before entering the adsorbers

Application of membrane technology for gas recovery:

- hydrocarbon vapors

- hydrocarbon vapors in shipping

- aromatic substances

- gas tank vapors

- PE production process

- ethylene C2H4 recovery

- nitrogen N2 recovery

- PP production process

- propylene C3H6 recovery

- nitrogen N2 recovery

- EO or EG production process

- ethylene C2H4 recovery

- PVC and rubber production process

- monomer regeneration

- recovery of sealing gases from shaft seals

- methanol and monoxide production process (methane pyrolysis)

- hydrogen H2 recovery

- biorefinery operations

- hydrocarbon recovery

- Hydrogen H2 recovery

- Methane production process

- Hydrogen H2 recovery

- CO2 recovery

- CO2 recovery and capture

Application of membrane technology for the recovery of liquid mixtures using OSN nanofiltration:

- biofuel processing

- oil and LNG processing

- waste oil processing

- Recovery of homogeneous catalysts

- Concentration of mother liquor

- Decolorization and purification of essential oils

- Decolorization and purification of hemp extracts

- Purification of proteins or API active pharmaceutical ingredients

- Purification and recovery of solvents

Application of membrane technology for the recovery of liquid mixtures using pervaporation:

- ethanol dehydration (dehydration unit)

- bioethanol dehydration (dehydration unit)

- isopropanol dehydration (dehydration unit)

- dehydration of organic solvents (dehydration unit)

- dehydration of other substances: C2-C5 alcohols, cyclohexanol, ketones (acetone, MEK, MIBK), ethers (methyl acetate MeAc, ethyl acetate EtAc, butyl acetate BuAc, acetonitrile, trimethylborate)