Coalescers

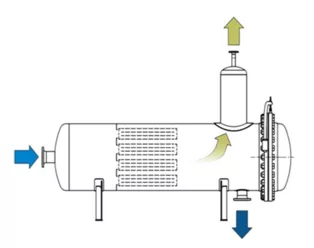

Cartridges Coalescers

Coalescence separators offer a continuously reliable and low‐maintenance separation of oil from oil‐water mixtures while maintaining high efficiency.

After the oil‐water mixture has flowed through the coalescence elements, two phases are formed. Oils or other hydrocarbons rise and collect in a separation chamber.

From there, the oil can be drained to be reused or disposed of.

Coalescence separators are only functional if the process stream contains only small amounts of emulsifiers.

The coalescence separators are individually designed and fulfil and often exceed the requirements acc. to DIN EN 858, class 1. Depending on the requirements, the separation efficiency achieved is normally higher than required by DIN EN 858

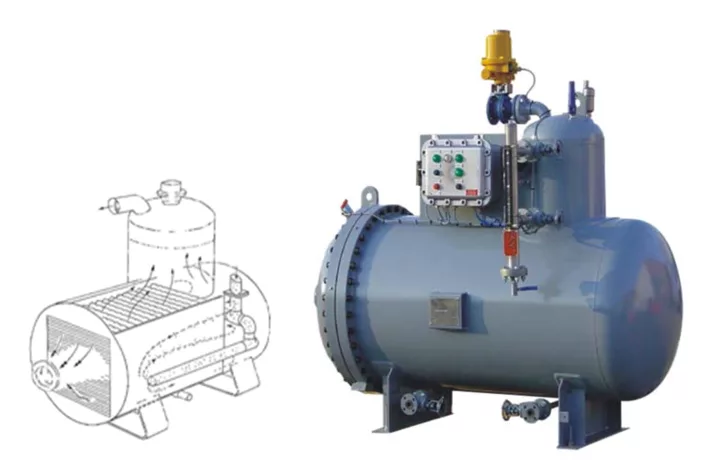

Coalescing plate separator

Most physical mixtures of hydrocarbons and water are separated by gravity. Since hydrocarbons have a lower specific gravity than water, they tend to float to the surface of the liquid mixture. If specific gravity of hydrocarbons is closed to water or the droplet size is small, spontaneous separation can be very time-consuming.

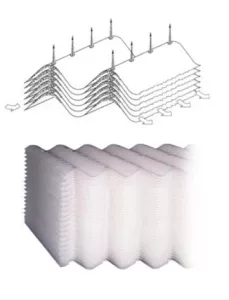

Working principle of coalescing plate separator

Coalescing plate separator consists of modules made up of a set of oleophilic plates placed close together and shaped to ensure laminar flow and droplet rising according to Stokes’ law.

Oily water is fed into the separator through an inlet pipe placed at sufficient depth under water surface and passes horizontally through the separator. Velocity in the inlet pipe has to minimize turbulence and thus droplet size reduction. An inlet baffle directs solid particles towards a bottom out of the separator area, while the hydrocarbon droplets are directed upwards. The hydrocarbon droplets contact the bottom part of the oleophilic plates, wetting the surface, and are trapped on the surface of the plates. Droplets cluster on the plate surface and form larger droplets or film. Hydrocarbon droplets rise up and are separated if they reach the surface before the horizontal water stream carries them away to the outlet. Hydrocarbons accumulated on the surface of the separator are removed by skimmer or manually (in the case of underground separators) into oil tank. The remaining oily water is then directed to the plate separator to remove remaining hydrocarbons.

Separation is carried out in the following basic steps:

- Removal of large hydrocarbon droplets upstream the plate module

- Capture of small droplets at the bottom part of the plates

- Clustering of small droplets into larger droplets or film

- Rising up of droplets and film to the surface of the separator and collecting them into oil tank

Separation of solid particles

Besides the separation of hydrocarbons from water, the plate separator is effective for removal of solids. Solid particles settle on the surface of the plates from above and slide down to the holes. They fall through the holes and accumulate at the bottom of the separator.

Application

Separation of hydrocarbons and solids from water in the following fields:

- Processing and transport of hydrocarbons (refineries, etc.)

- Storage terminals (removal of sludge from tanks, etc.)

- General industry including machining (coolants, etc.)

- Separation or recovery of other liquids and solids

- Contaminated rain or rinse water treatment

- Other applications such as oil extraction, cargo ships, etc.

Advantages:

- Small dimensions

- Minimal maintenance

- No moving parts

- Economical water treatment solution

- Provides the fastest possible separation of hydrocarbons and solids

- Under normal operating conditions:

- does not require pre-filtration

- no pump or compressor required

- requires only occasional flushing with water

Conditions and quality of separation

The quality of separation significantly depends on the input conditions. Surfactants (soaps, detergents, etc.) are used to break the bonds of oils and lubricants and dissolve them in the aqueous phase. Therefore these substances have a decisive adverse effect on the separation efficiency. Pumps, valves and other equipment causing shearing effects break the droplets into smaller ones and complicate the separation. For this reason, gravity feed to the separator is preferred. If it is not possible, low shear pumps are recommended. The ideal feed piping has a large diameter, minimum fittings and valves (low shear ones are preferable).

Information required to calculate the plate separator:

- Application field

- Water flow rate

- Temperature range

- Hydrocarbon type and their specific gravity

- Input hydrocarbon quantity in ppm – normal and max. value

- Required hydrocarbon concentration values at the outlet

- Dimensional limitation of separator size

- Type, size, quantity and specific gravity of solid particles

- Type of water (fresh, saline) and its specific gravity

- Presence and type of surfactants (detergents, etc.)

- Gravity feed or pump system (type and size of pump)