Drying and dewatering of solids

We supply dryers for various applications based on several physical principles. Based on your requirements for the drying method and the final product, we will offer you an appropriate solution. We focus primarily on continuous processes based on spray dryers, evaporator-based dryers, i.e., vertical and horizontal cylindrical dryers with built-in components, or dryers with rotating decks.

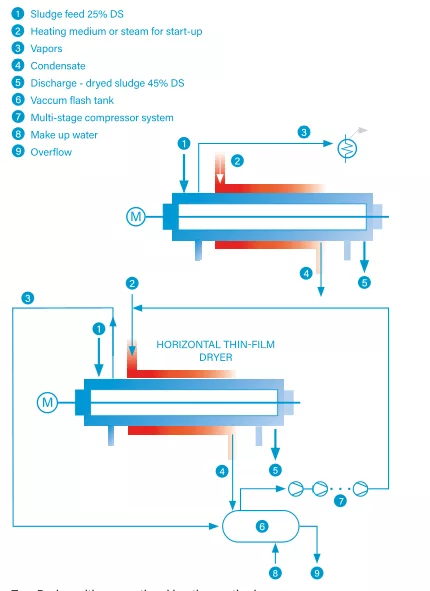

Cylindrical horizontal dryers using „thin-film“ technology

- The medium to be dried is distributed continuously around the entire circumference of the heating wall. Special wiper elements continuously renew the contact between the substance and the heating wall and ensure that the product flow continues.

- As the solid rotor blades do not touch the heating jack- et (defined gap), incrustation or blockage of the heating surface is avoided and liquid substances can be dried to powder form despite the gentle process.

- Applications:Slurry – Sewage sludges Process- and industrial sludge, Municipal sludge, Chemical products (precursors or intermediates), Saline solutions, Moist solids, Suspensions, Pastes

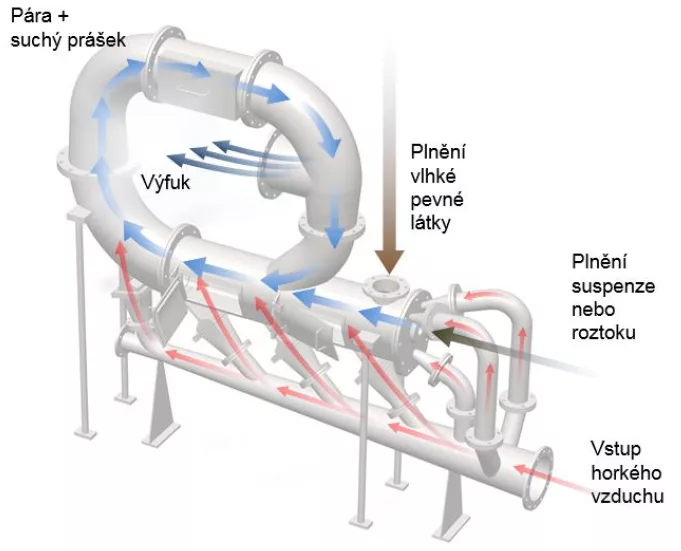

Spray turbo dryer

- Instant drying (flesh) of solid substances

- Applications: drying of minerals, chemical, pharmaceutical and cosmetic products, pigments and ceramics, plant protection products, plastics, waxes and foodstuffs

Multiple stage rotor dryer

- Dryer consists of a stack of slowly rotating circular trays. Material is fed onto the top tray. After one revolution the material is wiped onto the next lower tray where it is mixed, leveled, and then after one revolution, is wiped to the next tray where the operation is repeated. The trays are contained in an enclosure in which heated air or gas is circulated by internal fans

- Applications: powders, pastes, crystals, granulates, sawage, large pieces, solid particles, centrifuge or other filter waste cakes, pellets, flakes, etc.

- Operates as a dryer, cooler, reactor, heat treater, calciner, humidifier, agglomerator, sublimer, roaster, in combination if required.