Gear Pumps

We offer explosion proof and seal-less pumps for the petrochemical industry, pumps with minimal surface roughness for the pharmaceutical and food industry and high pressure pumps for dynamic applications etc.

External gear pumps are self-priming, non-pulsating and reversible pumps that work best on clean, lubricating fluids with a viscosity thicker than water. Two gear teeth, one idler and one driver, mesh together to transfer the liquid.

Areas of application:

Food industry:

Vegetable oils, butter, vegetable butter – margarine, treacle, chocolate, fondant, flavours, liquorice, chewing gum, vitamins, syrups, gelatine, etc.

Pharmaceutical and cosmetics industry:

Amino acids, skin solutions, shampoos, vitamins, etc.

Chemical and petrochemical industry:

Alcohols, additives, bases, esters, glycerines, resins, hardeners, isocyanates, oils, monomers, phenols, acids, biodiesel, asphalts, bitumens, tar, glues, paraffins, etc.

Polymers:

Cellulose acetate, Nylon 66, monomers, oligomers, prepolymers, PS, PET, PBT, PA, PVC, PC, PS, SAN, ABS, PUMMA, HDPE, LDPE LLDPE, HIPS, PP, PE, PEEK, POM, polysulfones, biopolymers, etc.

Metering/Dosing system (WDS):

Enables accurate volume measurement of low and high viscosity media even at high pressures and temperatures. The system consists of two gear pumps connected in series. One pump is for measuring and the other one for increasing pressure. The system is precisely controlled by a PLC control system with an accuracy of less than 0.01% according to the medium.

Special pumps:

Pumps made of ceramics, tantalum, titanium, submersible pumps, with magnetic drive, for highly corrosive media and other special designs according to customer requirements.

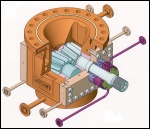

Model CHEM

Transport and Metering Gear Pump

| Viscosity: | 0,5 – 10.000.000 mPa.s |

| Temperature: | up to 450oC |

| Pressure: | Input: vacuum up to 15 bar Output: up to 200 bar up to 700 bar with magnetic drive |

| Capacity: | 1,28 – 12.000 cm3/rev |

| Housing: | Stainless steel, hastelloy, tantalum, titanium and ceramics |

| Gears: | Any workable metal and ceramics |

| Sliding bearing: | Carbon, NiAg, Silicon Carbide, Zirconium Oxide Tool Steel, special materials |

| Shaft seal: | Single or double mechanical seals, gaskets, |

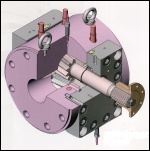

Model POLY

| Viscosity: | Up to 40.000 Pa.s |

| Temperature: | Up to 350oC |

| Pressure: | Input: vacuum up to 40 bar |

| Capacity: | 4,7 – 12.000 cm3/rev |

| Body: | Stainless steel, hastelloy, cast steel |

| Gears: | Nitrided steel, tool steel, special materials |

| Sliding bearing: | NiAg, Al-bronze, tool steel, special materials |

| Shaft seal: | Single and vacuum Viscoseal, seals, mechanical seals, magnetic coupling |

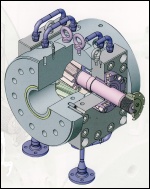

Model EXTRU

| Viscosity: | 1,0 – 40.000 Pa.s |

| Temperature: | Up to 450oC |

| Pressure: | Input: vacuum up to 200 bar Output: up to 700 bar |

| Capacity: | 4,7 – 12.000 cm3/rev |

| Body: | Steel, stainless steel for PVC applications |

| Gears: | Nitrided steel |

| Sliding bearing: | NiAg, Al-bronze, ceramics, tool steel, special materials |

| Shaft seal: | Viscoseal, seals, seals/gaskets |

Model BOOSTER

Viscosity: | Up to 40.000 Pa.s |

Temperature: | Up to 350 °C |

Pressure: | Input: vacuum up to 100 bar Output: up to 350 bar |

Capacity: | 4,7 – 12.000 cm3/rev |

Body: | Stainless steel, Hastelloy, cast steel |

| Gears: | Nitrided steel, tool steel, special steel |

| Sliding bearing: | NiAg, Al-bronze, tool steel, special materials |

| Shaft seal: | Viscoseal, seals, seals/gaskets |