Dynamic in-line mixers

Dynamic in-line mixers provide efficient continuous mixing (blending, homogenization, reactors, etc.), enabling the replacement of batch mixing in vessels. The result of many applications is significant savings in investment, operating costs, and time.

Areas of application

- Cosmetics industry

- Pharmaceutical industry

- Environmental technology – wastewater treatment plants, etc.

- Chemical, petrochemical, and refining

- industries

- Plastics production (extruders)

- Textile industry

- Paper industry

- Food industry

Examples of mixing applications

- Silicone dyes, paints, varnishes, adhesives

- Oils, oil with water or glycerin

- Sodium hydroxide and water for paper production

- Phenolic resins, acids

- Paraffins, waxes

- Bitumen – asphalt / polymers/

- Rubber granulates

- Biodiesel, degumming

- Vegetable oils

- Wastewater treatment plants: water/polymers, flocculant formation, pH adjustment

- Sauces

- Brewer’s yeast, lecithin

- Sweets: candies, dragees, furé, etc.

- Yogurt, milk drinks, juice concentrates

- Cottage cheese, creams – production of desserts and pastries

- Cheese (mixing steam, herbs, or salt solutions)

- Chocolate, bars, caramel, cocoa, candies, pralines

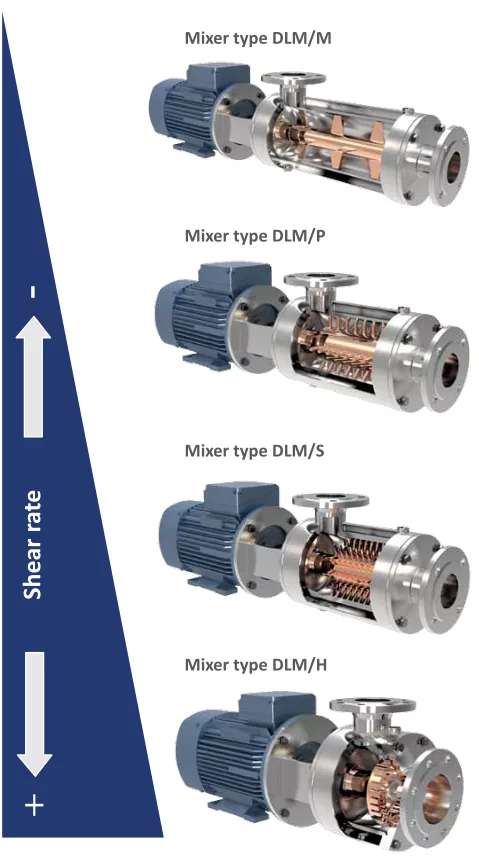

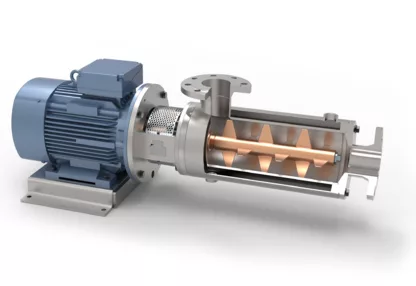

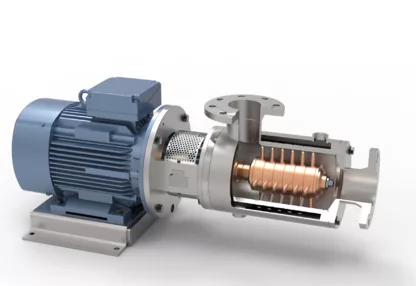

DLM / M model

- Gentle mixing

- Mixing elements on axial rotor

- Pressure: Standard up to 6 bar max.PN100

- Capacity: 10 – 40,000 L/h

- Power: 0.5 – 7 kW

DLM / S model

- Intensive mixing, foaming option

- “Star” mixing elements on both the axial rotor and stator

- Pressure and capacity depending on the liquid and mixing requirements (160 bar and above)

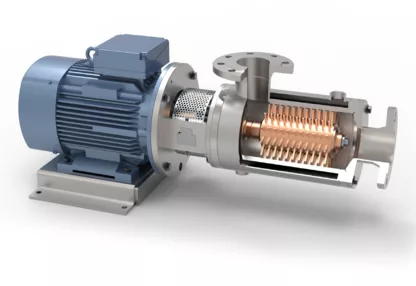

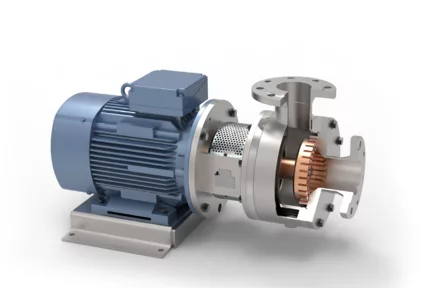

DLM / P model

- Intensive mixing, foaming option

- Mixing elements “pins” on both the axial rotor and stator

- Pressure and capacity depending on the liquid and mixing requirements (160 bar and above)

DLM / H model

- Homogenization (high-intensity mixing and shear forces)

- Mixing elements on the radial rotor and stator with narrow tolerances

- Pressure: Standard up to 120 bar

- Capacity: 10–60,000 L/h

- Power: 2.2–120 kW

- Speed: 1,000–7,200 rpm

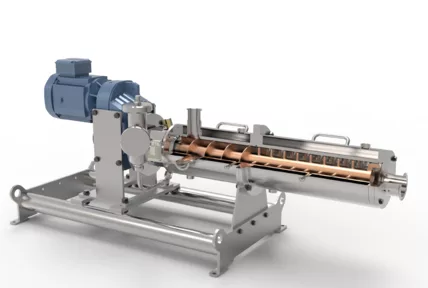

DLM / FS model

- Continuous mixer for liquids and solids (up to 20 mm in diameter)

- Depending on the geometry of the mixing elements, gentle mixing or shear mixing can be achieved

- The crushing elements are located on the radial rotor and stator. The gaps are adjusted according to the application

- Pressure: Standard up to 6 bar, depending on product viscosity

- Viscosity: 1–10,000,000 mPas

- Temperatures: 0–300 °C

- Capacity: 100–7,000 L/h, higher on request

- Power: 1.5–11 kW

- Material: AISI316L, others on request